Cyclic Corrosion

Standard corrosion cabinet evaluations define conditions for a “static” environment, however, cyclic corrosion cabinet exposures are dynamic in nature and better emulate real world conditions. The cyclic corrosion exposures are still accelerated tests where the variable conditions are extremes. The parameters that are typically varied include the chemical solution applied to the part, humidity, and temperature. The test conditions are varied over a period of time that is programmed and defines the “cycle”. The exposure cabinets required for these cycles need additional controls and programmability over standard salt spray and humidity cabinets.

Fractions Of The Cyclic Corrosion Cycle

Chemical Exposure

The exposure fraction of the cycle defines an exposure solution that is applied to the target parts. Often times this solution is the same as a typical salt spray solution (5% sodium chloride), however, often times it is varied as more extreme or varied in the ionic constituents. For example, the GMW14872 exposure solution is a mixture of sodium chloride (0.9%), calcium chloride (0.1%) and sodium bicarbonate (0.075%). The method and periodicity of application of this solution is also defined in the reference standard. The solution may be required to be fogged into the chamber, like standard salt spray, spray applied at varying intervals, or even immersion (where the chamber is flooded with the liquid or the parts are removed from the cabinet and immersed). In addition, the other variables are also defined such as the cabinet temperature and relative humidity.

Humidity and Temperature

Often times a fraction will be specified where no chemical exposure will be occurring but the humidity and temperature will be specified. In addition, several specifications include rates needed to reach the steady state conditions (such as the Ford L-467 specification). The humidity can be controlled and varied using conditions such as wet bottom heating, fogging, or incoming air conditioning. Temperature controls are adjusted using constant feedback of the chamber heaters. Where the specification requires temperatures below ambient, mechanical cooling is often employed of the cabinet jacket.

Drying

Most of the cycles performed require a drying cycle, which will revert to a high temperature and low humidity condition. This will typically involve either venting the cabinet, purging the cabinet with air while draining any aqueous fluids, or transferring the parts to a dry cabinet or oven.

This fraction is typically in preparation for return to ambient conditions.

Ambient

In the ambient fraction the cabinet is typically returned to a defined ambient condition that would simulate a controlled laboratory setting (such as 25C with 40% RH). Again, often times the rates to return to this condition are specified and recorded. The ambient fraction can also combine the chemical exposure fraction such that chemical exposure is actually performed during the ambient fraction.

Defining The Cyclic Corrosion Cycle

The cyclic corrosion cycle is defined as putting the above fractions together in a specific order, with conditions in each fraction (and rates to reach the equilibrium states) specified in the referenced methods. The total cycle time is defined as the sum of times in each fraction. Additionally, the testing method will determine the number of cycles that comprise total exposure. In several specifications, the cycle is defined over a 24 hour period so that the monitoring and the logistics of deploying each cycle will be efficacious.

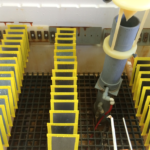

Cabinet Controls

Many of the cyclic corrosion specifications will have similar controls as the salt spray and humidity methods. During fogging cycles the rate of solution collection over a certain area can be determined and recorded. The fogging solution pH and specific gravity determinations can be made. Modern day cabinets also enable real time logging of temperature and humidity conditions as well as rate changes.

In addition, several specifications also assess corrosion efficacy by placement of standard materials such as mass loss coupons. These coupons are exposed in the same manner as the test pieces and are consumed during testing and removed at specified time periods to assess the corrosion rates. Some specifications will even define the total cycles performed as the time in which a particular mass loss is obtained from the standard coupons.

Evaluation of Test Specimens

As with salt spray and humidity specimens, evaluation criteria is varied and often specified with supplemental evaluation methods. For example, evaluation can be described simply as “no blisters or change in appearance permitted”. Time to white and/or red corrosion is often an evaluation criteria. Distance of creep-back from a scribe or an adhesion test is often specified as well for evaluation. The specimens will typically require photographic evidence of the condition after exposure or even during the exposure cycles.

Cyclic Corrosion Methods Performed

The overwhelming majority of the cyclic corrosion testing requirements come from the automotive OEMs, and unfortunately all of them are different in their cycle definitions and cabinet requirements. That being said, a separate cabinet is typically required for each testing specification offered, or the test methods have to be run sequentially to accommodate multiple test specifications. As a majority of the accelerated corrosion cycles involve typically long term exposure, lead time for the testing can often times be extended due to availability of the cabinet to run a certain specification. Although capable of more cyclic corrosion specifications, we tend to concentrate on three specifications that are the majority of our inquiries and include:

GMW14872 – General Motors comprehensive cyclic corrosion specification

CETP 00.00-L-467 – Ford Motor Company comprehensive cyclic corrosion specification

SAE J2334 – SAE Cycle definition for de-facto cyclic corrosion

In addition to the above routinely performed specifications, several others are routinely performed in the automotive sector which includes the following:

Chrysler LP-463PB-22-01, Delphi DX900115, FLTM BI 123-01, FLTM BI 123-02, FLTM BI 123-03, Honda DWG.5100Z-SE0-0000, Navistar CEMS GT-7D, NES M0158, VDA 621-415.

Several of these specifications require sub-ambient temperatures and/or immersion exposure fractions.